The Chassis

It’s all about the chassis, from space frame to monocoque we’ve figured out some interesting rules and limitations which has made the engineers back in the factory to go “oh shit” every year during the development of next year’s car.

Measurements

Talking about rules there comes the measurement first in everyone’s thought. Well that’s natural. But it’s really fundamental and easy too to restrict a car’s body in terms of measurement. A F1 car should not be wider than 2000mm and no taller than 950mm. Length isn’t considered as a factor yet as there comes other external things like rear and front wings which also got some limitations.

Weight

Weight is also a serving potential in the rule book of FIA as it is revised from 733kg to 740kg as the max weight of the car including the minimum driver weight of 80kg so extra cheese is ok from this season LOL !.

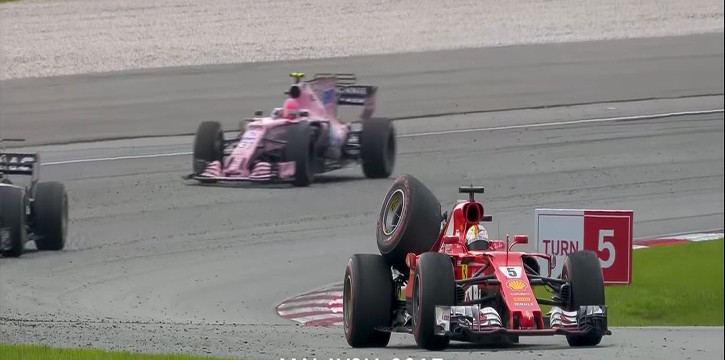

Wheels

The chassis should contain only four external wheels , where only the rear wheel should get the power from transmission and the front wheel is just for direction purpose – obviously steering. After going through out the car with measurement perspective it’s time to sneak peak for safety.

Rules for Safety!

Safety was the foremost reason for the strict formulations and regulations applied to the sport every year. Here, the safety cell and Halo is doing the job for the drivers. The safety cell aka cockpit is the basic structure of the monocoque chassis, it has a primary task of protecting the drivers from the external crash in the grid and the secondary task of preventing the driver in case of Fire accidents. Thank god to lightweight driving suits but monocoque does it better.

With the effect of a new safety structure rule, the Halo was mandated from 2018 season. It is said to be the more rigid structure in the entire car also saved many drivers from debris flying on the grid while the yellow flag is waving.

Aero limitations (wind tunnel test)

There are multiple numbers of tools are used to design and analyse the monocoque. Teams started investing millions of dollars in aerodynamic department to get a better car over the season. FIA has revised its regulations over the aero department this time. The board restricted the wind tunnel usage to 25 hours a week for testing the new chassis design .This diminished the prolong wind tunnel test of some constructors on the grid.

But the software segment left untouched till date as there is not restrictions laid on that path. Software which used to design like CAD (CATIA), CAM and CFD tools are safe from FIA’s eyes. These are some common chassis design and analyse platforms.

>>The Rules of Formula One. How the F1 sport played?<<

Crash test (Technical data source: Wikipedia)

Apart from measurements, safety and design complexity the teams must clear the mandated crash test and to clear the required standards.

Impacts

- There is a 30 mph (48 km/h) head-on impact into a steel barrier; “average deceleration must not exceed 25g”, with a maximum 60g for a minimum 3 milliseconds, with no damage to the chassis beyond the nose section. The same chassis must then sustain a rear impact from a sled travelling at 30 mph (48 km/h), with no damage in front of the rear axle.

- The roll hoop is not permitted to crush beyond 50 mm (2.0 in), and structural failure is only permitted in the top 100 mm (3.9 in) of the body.

- Side impacts by a 780 kg (1,720 lb) object at 10 m/s (22 mph) must be decelerated at less than 20g, and absorb no less than 15% and no more than 35% of the total energy; 80 kN (18,000 lbf) cannot be exceeded more than 3 milliseconds.

- The steering wheel must survive the impact of an 8 kg (18 lb) 165 mm (6.5 in)-diameter object at 7 m/s (16 mph) with no deformation of the wheel or damage to the quick-release mechanism.

- In addition, there are “squeeze tests” on the cockpit sides, fuel tank, and nosebox. The cockpit must survive a 25 kN (5,600 lbf) pressure with no failure; for the fuel tank, 12.5 KN (2,800 lb) is applied. A maximum 3 mm (0.12 in) deformation is allowed. For the cockpit rim, the figures are 10 kN (2,200 lb) and 20 mm (0.79 in). The nosebox must withstand 40 kN (9,000 lb) for 30 seconds without failing.

Electrical and computer systems

- Onboard electrical and computer systems, once inspected at the start of the season, may not be changed without prior approval. Electronic starters and launch control are forbidden. The computers must contain a telemetric accident data reporting system where the datas are collected for reference purposes.

To be continued………

Author

Thiruvarasan . V